Barrel nuts and bolts are not just ordinary components, but fundamental ones that play a crucial role in various applications. These specifically designed types of fasteners stand out due to their unique properties. When used together, they provide an incredibly strong and stable connection, ensuring the structures they’re used in are firmly held together. Their importance cannot be overstated, especially considering the critical role they play in maintaining structural integrity.

Their unique design and the strength they provide make them indispensable in both commercial and home applications. Despite potential challenges in alignment during assembly, their advantages significantly outweigh these minor inconveniences.

Their design allows for the creation of robust structures that can withstand significant amounts of stress and weight. With careful assembly and alignment, barrel nuts and bolts provide an excellent solution for creating strong, stable connections.

Design and Features

Barrel nuts are characterized by their unique shape, resembling a barrel. The bolts are distinct due to their threading and size. They are made from different materials based on their application.

They are usually made of high-strength materials to ensure they can withstand the pressure and weight they are subjected to in their applications. Whether it’s in the assembly of a heavy piece of furniture or in more industrial applications, their contribution to structural integrity is invaluable.

Common Applications and Uses

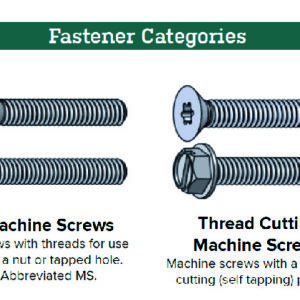

Barrel nuts and bolts are commonly used in applications requiring strong, secure connections. They are prominently used in the assembly of flat-pack furniture, bicycle assembly, and even in some aerospace applications.

Shape and Design of Barrel Nuts

Barrel nuts are typically cylindrical with an internal thread. They are designed to be used with a bolt that fits inside.

They have a hole drilled through the center which allows a bolt to be threaded through. One end of the barrel nut is exposed to where the bolt can be inserted, while the other end is typically flush with the surface of whatever it is being fastened to.

Size and Threading of Bolts

The bolts that are designed to be used in conjunction with barrel nuts are manufactured with a very specific threading pattern and size. This precise design ensures that they can fit perfectly into the barrel nut, creating a secure and stable connection. The attention to detail in the threading and sizing of these bolts is critical, as any discrepancies could result in an unstable fit, potentially compromising the integrity of the connection between the bolt and the barrel nut.

Material Types

Barrel nuts and bolts are integral components in construction and manufacturing, and as such, the materials used in their making are of utmost importance. While the specific materials can vary based on the intended use and application, typically, these components are made from high-quality metals. Stainless steel and brass are the most commonly used materials for manufacturing barrel nuts and bolts. These materials are chosen because they offer superior durability, ensuring that the barrel nuts and bolts can withstand a high level of stress and use. The stainless steel provides high resistance to corrosion and heat, making it suitable for applications that require a high degree of durability and resilience. On the other hand, brass offers excellent machinability, making it a good choice for applications that require precise and intricate detailing.

How They Work Together

The barrel nut and bolt operate together in a symbiotic relationship, creating a secure and unyielding connection between two components. The bolt, a long body with a helical groove, is meticulously inserted into the barrel nut, a cylindrical fastener with internal screw threads. As the bolt is tightened, it interlocks with the barrel nut, significantly enhancing the strength and stability of the connection. This mechanical coupling ensures a robust assembly, capable of withstanding high levels of stress and usage, thus ensuring the longevity and reliability of the overall structure.

Common Uses

Barrel nuts and bolts are essential components in a myriad of applications across various industries due to their robustness and the strong, secure connections they provide. These fasteners are prominently utilized in the furniture construction industry, especially in the assembly of flat-pack furniture, where their strength and stability are key to ensuring the durability of the final product.

In the manufacturing industry, barrel nuts and bolts are often used in the assembly of machinery and equipment due to their ability to withstand high levels of stress and usage, thus ensuring the longevity and reliability of the machinery. For instance, they are used in the automotive industry in the assembly of car parts where a secure connection is required.

In the aerospace industry, these fasteners are implemented in the construction of aircrafts, where their strength and durability are critical in ensuring the structural integrity of the planes. Owing to their resilience, barrel nuts and bolts are also utilized in the marine industry, particularly in the construction of ships and other seafaring vessels where they are exposed to harsh environmental conditions.

Moreover, in the construction industry, barrel nuts and bolts are used in the assembly of structures that require a high degree of durability and resilience. They are also used in applications that require precise and intricate detailing, as they offer excellent machinability.

In sum, the widespread use of barrel nuts and bolts in various industries underlines their versatility, strength, and their indispensable role in creating secure and durable connections.

Advantages and Disadvantages

The barrel nuts and bolts have a significant edge over other types of fasteners due to their superior strength and durability. Manufactured from robust materials, they can withstand high levels of stress and strain, making them an ideal choice for applications where longevity and reliability are crucial. In addition to their sturdiness, these fasteners are also appreciated for their simplicity of use, which means even individuals with minimal technical skills can handle them with relative ease. However, despite these benefits, barrel nuts and bolts can present a certain level of challenge. This is particularly true if the alignment of the bolt is not perfectly in sync with the barrel nut. If the alignment is incorrect, it can make the process of fastening more cumbersome and possibly lead to issues down the line.

Durability and Strength

Barrel nuts and bolts are renowned for their exceptional durability and strength. This is largely due to the meticulous design and the high-quality materials from which they are made. The design ensures that these components fit together perfectly, creating a secure connection that can withstand significant stress. Additionally, the materials used in their construction, typically robust metals, contribute to their longevity and reliability. As such, barrel nuts and bolts provide a connection that not only lasts but also maintains its structural integrity over time.

Ease of Use

The design of these fasteners, which is both innovative and practical, makes them incredibly simple to use. They have been engineered in such a way that the user needs nothing more than a basic tool, like a screwdriver or a wrench. This uncomplicated design not only makes them accessible to a wide range of users, whether they are professionals or do-it-yourself enthusiasts, but also ensures a quick and efficient assembly or repair process.

Potential Challenges

When engaging in the assembly process, one of the primary challenges that may be encountered is the correct alignment of the bolt with the corresponding barrel nut. This step is crucial, as the bolt and the barrel nut need to be perfectly in sync for the assembly to progress smoothly. If they are not aligned correctly, it could result in complications during the assembly process, which could potentially lead to a significant increase in the time and effort required to complete the assembly. Therefore, careful attention must be paid to this step to ensure a seamless assembly process.

Conclusion

Barrel nuts and bolts play a vital role in various applications, particularly in furniture construction. They are strong, durable, and relatively easy to use, making them a popular choice for many industries.

Q & A

How to install barrel nuts and bolts?

To install barrel nuts and bolts, start by aligning the pieces you wish to connect, ensuring that the pre-drilled holes for the barrel nut and bolt line up. Insert the barrel nut into its hole, making sure the threaded hole inside the nut aligns with the bolt hole in the other piece. Then, insert the bolt into its hole and through the hole in the barrel nut. Use a screwdriver or wrench to turn the bolt clockwise, threading it into the barrel nut. Continue tightening until the connection is secure, but be careful not to over-tighten as this can strip the threads or damage the materials. Always ensure you have the correct size of barrel nut and bolt for your specific application, and remember that proper alignment is crucial for a successful installation.

How to use a barrel nut and bolt?

To use a barrel nut and bolt, you first need to align the components you wish to connect, ensuring that the pre-drilled holes for the barrel nut and bolt are perfectly lined up. Insert the barrel nut into its designated hole, taking care that the threaded hole within the nut aligns with the bolt hole on the other part. Then, introduce the bolt into its hole and through the hole in the barrel nut. Utilize a screwdriver or wrench to turn the bolt clockwise, threading it into the barrel nut. Keep tightening until you achieve a secure connection, but be mindful not to over-tighten as this could damage the threads or the materials involved. Remember, the key to a successful installation lies in the correct alignment and size selection of the barrel nut and bolt for your specific task. Following these steps will ensure a robust and stable connection, reinforcing the strength of your structure.

What is a barrel nut and bolt?

A barrel nut and bolt are crucial fastening components with unique properties and design features. The barrel nut is typically cylindrical with an internal thread, designed to fit with a bolt. This bolt is manufactured with a specific threading pattern and size, ensuring a perfect fit within the barrel nut and creating a secure, stable connection. These components are often made from high-quality metals like stainless steel or brass for superior durability. When combined, the barrel nut and bolt provide an exceptionally strong and stable connection, making them fundamental in various applications, including furniture construction, machinery assembly, and even aerospace applications. Their strength, durability, and relative ease of use underscore their importance in maintaining structural integrity.

How strong are barrel nuts and hex bolts?

Barrel nuts and hex bolts offer exceptional strength due to their unique design and the materials used in their construction. They are typically made from durable metals like stainless steel or brass, which can withstand high levels of stress and use. When used together, the precision threading of the bolt aligns perfectly with the internal threads of the barrel nut, creating a secure and stable connection. This strong connection enables the assembly to support significant weight and resist various forces, making barrel nuts and hex bolts an ideal choice for applications requiring robust and reliable fasteners. Their strength and durability are evident in their widespread use, from furniture assembly to industrial and aerospace applications.