Fasteners play a crucial role in mechanically joining and securing multiple parts together. However, their performance and service life are significantly influenced by factors such as type, quality, shape, and material. Therefore, understanding the different varieties of fasteners, including bolts, nuts, and washers, is essential for selecting the right fastener and supplier for your project.

At Hightensilenutbolts.com, we take pride in offering a wide range of stock and custom fasteners that prioritize durability, high performance, and competitive pricing. In this guide, we provide an overview of a selection of fasteners from our inventory to assist you in choosing the optimal product for your specific fastening application.

An Overview of Bolt Types and Configurations

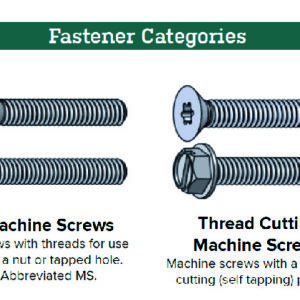

Bolts are versatile structural fasteners with a vast array of configurations to suit various materials and strength requirements. Each type of bolt differs primarily in thread specification, length, and head shape, resulting in different functions. Bolts require a complementary nut or mating part for installation and are generally not tapered.

However, the terminology for bolts is often inconsistent and incorrectly interchanged with screws, so it’s essential to select bolts based on project specifications.

Types of bolts include:

- Carriage bolts with a domed or countersunk head with a square underside for wood and masonry applications

- Flange bolts with an integrated flange that serves as a washer component to evenly distribute loads

- Plow bolts, a heavy-duty type of bolt similar to carriage bolts with a square-shaped countersunk top, or a domed design for industrial machinery applications

- Hex head bolts and cap screws, defined by their hexagonal head shape, requiring installation with a wrench, and available in various lengths and threading varieties

- Square head bolts, also defined by their head shape, with tooling gripping that allows easy installation

- Socket head cap screws or Allen bolts with a flat chamfered top surface and smooth or knurled cylindrical sides, ideal for high-demand mechanical applications with their forged, heat-treated alloy.

- Other bolt types we can manufacture include anchor, belt, countersunk, lag, and T-handle bolts.

An Overview of Nut Types and Configurations

Nuts come in various shapes, sizes, materials, and thread patterns. While your choice of nut is somewhat influenced by the bolt you are using, considering factors like size and threading, it is still important to select the most suitable nut head shape and material for your specific application. Here are some common types of nuts:

- Coupling nuts: These cylindrical nuts join two male threads and can be used to add length to an installation.

- Flange nuts: Similar to flange bolts, these nuts have a round flange that acts as an external washer, ensuring more even load distribution.

- Hex nuts: Hexagonally shaped, these versatile nuts require a wrench for installation. Our supply includes finished hex, semi-finished hex, hex flange, hex jam, heavy hex, and slotted hex nuts.

- Lock nuts: Available in different shapes, lock nuts are used to secure other nuts and prevent them from loosening. Examples include all-metal lock nuts with top or side locking features, serrated hex flange nuts, and nylon inserts.

- Slotted nuts: Designed for use with cotter pins or safety wires, slotted nuts form a locking mechanism.

- Square nuts: Square in shape, these nuts have increased surface area and friction, reducing the risk of loosening.

- Wheel nuts: This broad category of nuts is specifically used in automotive wheel applications.

We also offer custom manufacturing for other nut types, including cap nuts, castle nuts, conical nuts, Keps nuts, thumb nuts, and wing nuts.

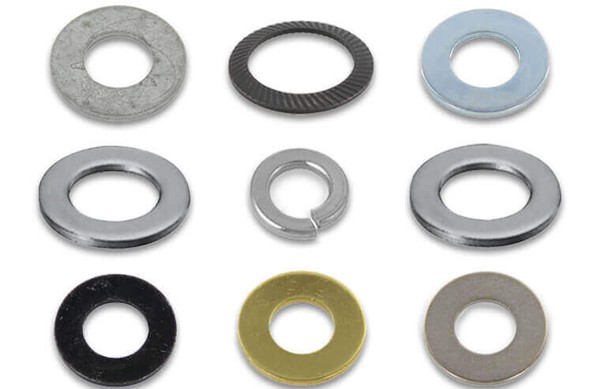

A Guide to Washer Types and Functions

Washers are disk-shaped components that play a crucial role in enhancing control over locking and friction when used with other fasteners. They provide various functions such as preventing loosening, protecting surfaces, and distributing pressure evenly during installation and use. Although washers have fewer variants compared to nuts and bolts, distinguishing between washer types remains important to ensure compatibility with your chosen bolt and specific fastening application.

Our range of standard washers includes:

- Beveled washers: These have a slightly angled surface, allowing them to join materials that are not parallel to each other.

- Flat washers: The most common type, flat washers provide a larger surface area for improved load distribution. They come in different thicknesses to accommodate various hold strengths.

- Lock washers: Available in various shapes, such as helices, toothed rings, conical, or spring, lock washers are designed to prevent fastener slippage in demanding applications. They are commonly used in environments with high levels of vibration.

- Structural washers: These heavy-duty washers are specifically designed to withstand the high load pressures found in construction.

We are dedicated to providing you with the necessary washer types to meet your fastening needs, offering a range of options suited to different applications.

Important Considerations for Fastener Selection

When it comes to choosing the right fasteners for your specific application, Hightensilenutbolts recommends consulting with an engineer. An engineer can provide valuable expertise in identifying which fasteners to use, considering various factors that are crucial to the joint formation. Understanding how individual fasteners work together, thread patterns, material options, and finishing choices are all important considerations.

By involving an engineer in the selection process, you can save both time and potential issues in the long run. Their knowledge and expertise will ensure that the chosen fasteners are well-suited for your needs, resulting in efficient and effective fastening solutions.

Reach out to us today to connect with our team of engineers who are ready to assist you in finding the best fasteners for your specific application.