Nuts and bolts, often overlooked in their simplicity, are integral components that play a foundational role in the realms of construction and manufacturing. Serving as the basic building blocks for assembling structures and machinery, these unassuming fasteners are responsible for ensuring stability, durability, and reliability in a wide array of applications. From the assembly of massive skyscrapers to the intricate machinery powering industries, nuts and bolts form the essential connections that hold everything together, making them indispensable in the construction and manufacturing processes. Their significance lies not only in their basic function but also in their ability to provide strength, flexibility, and adaptability across diverse projects and applications. In essence, nuts and bolts are the unsung heroes that quietly contribute to the structural integrity and functionality of the physical world around us.

At first glance, nuts and bolts might appear as mere minuscule components, easily overlooked in the grand tapestry of construction and manufacturing. However, as we delve into the intricate world of engineering and assembly, it becomes abundantly clear that these seemingly small fasteners play a role of unparalleled significance. They are the silent architects, the unsung heroes that bear the responsibility of holding everything together.

In the vast landscapes of construction sites and bustling manufacturing floors, it is the nuts and bolts that form the backbone of every structure and machine. Like unassuming puzzle pieces, these essential fasteners create connections that withstand the test of time and environmental forces. The crux of their importance lies not only in their physical presence but also in their ability to provide stability, strength, and resilience.

As we embark on a journey to explore the intricacies of high-quality nuts and bolts, it becomes evident that these unpretentious components are the linchpin, the elemental force that ensures the solidity and coherence of the structures we encounter daily. Their significance, though often overshadowed, is undeniable, and it is this hidden influence that we aim to unravel and appreciate in the course of this exploration.

Function of Nuts and Bolts in Construction

Connecting Components

- Fundamental role in joining various construction elements, such as beams, columns, and panels.

- Form secure connections by tightening the nut onto the threaded end of the bolt.

Structural Integrity

- Essential for maintaining the structural stability of buildings and infrastructure.

- Distribute loads and forces evenly, preventing components from shifting or separating.

Disassembly and Maintenance

- Facilitate ease of disassembly for maintenance, repairs, or modifications.

- Allow for the removal and replacement of components without compromising the entire structure.

Adjustable and Secure Fastening

- Enable adjustments during construction to ensure precise alignment and fit.

- Provide a secure fastening method that resists loosening over time.

Load Distribution

- Distribute and transfer loads across interconnected components, preventing localized stress points.

- Contribute to the overall load-bearing capacity and resilience of the structure.

Versatility

- Suitable for a wide range of construction materials, including wood, metal, and concrete.

- Adaptability allows for diverse applications in construction projects of varying scales and complexities.

Flexibility in Design

- Allow engineers to design structures with flexibility, accommodating movement and expansion.

- Varied sizes and specifications contribute to the adaptability of nuts and bolts in different construction scenarios.

Nut and Bolt Structure

Nut Structure

A. Physical Characteristics:

- Small, typically hexagonal or square-shaped metal component.

- External surface may be knurled or flat for ease of grip during tightening.

- Contains a threaded hole running through its center.

B. Threaded Hole:

- The threaded hole inside the nut corresponds to the threads on the bolt.

- Threads are spiraled ridges or grooves designed to match those on the bolt.

- Thread pitch and type can vary based on the specific application and engineering requirements.

C. Types of Nuts:

- Hex Nuts: Six-sided shape, most common and versatile.

- Square Nuts: Four-sided shape, often used in conjunction with square bolts.

- Wing Nuts: Have two extended “wings” for hand-tightening without tools.

Bolt Structure

A. Physical Characteristics:

- Cylindrical metal fastener with a threaded end.

- Head at one end for applying torque during installation.

- Shaft with external threads designed to engage with the threaded hole in the nut.

B. Threaded End:

- The threaded end of the bolt passes through the nut.

- Threads on the bolt are matched to those inside the nut for secure fastening.

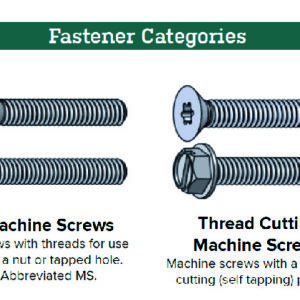

C. Types of Bolts:

- Hex Bolts: Have a hexagonal head for torque application with a wrench.

- Carriage Bolts: Have a rounded head and a square neck under the head, preventing rotation during tightening.

- Stud Bolts: Have threads on both ends and are often used for flange connections.

D. Shank:

- The unthreaded portion of the bolt between the head and the threads.

- Varies in length based on the specific application.

Materials Used in Manufacturing Nuts and Bolts

A. Steel

1. Overview:

a. Most common material for nuts and bolts.

b. High strength and durability.

2. Types:

a. Carbon Steel: Standard choice for general applications.

b. Alloy Steel: Enhanced strength and toughness through alloying elements.

B. Stainless Steel

1. Overview:

a. Resistant to corrosion and rust.

b. Ideal for applications in corrosive environments.

2. Types:

a. Austenitic Stainless Steel: High corrosion resistance.

b. Martensitic Stainless Steel: High strength and hardness.

C. Brass

1. Overview:

a. Non-ferrous metal with excellent corrosion resistance.

b. Commonly used in electrical and decorative applications.

D. Titanium

1. Overview:

a. Lightweight yet strong.

b. High corrosion resistance.

c. Frequently used in aerospace and medical applications.

E. Aluminum

1. Overview:

a. Lightweight.

b. Good corrosion resistance.

c. Commonly used in applications where weight is a critical factor.

F. Alloy Materials

1. Overview:

a. Mixtures of different metals for tailored properties.

b. Examples include aluminum alloy, nickel alloy, and copper alloy.

G. Exotic Materials

1. Overview:

a. Uncommon materials chosen for specific applications.

b. Examples include Inconel for high-temperature resistance.

Considerations for Material Selection

A. Environmental Conditions:

1. Corrosion resistance for outdoor applications.

2. Resistance to extreme temperatures or chemicals.

B. Strength Requirements:

1. High tensile strength for load-bearing applications.

2. Impact resistance for dynamic loads.

C. Weight Considerations:

1. Lightweight materials for applications with weight constraints.

2. Heavy-duty materials for structural stability.

D. Cost Factors:

1. Balancing material quality with project budget.

Role of Design in Determining the Strength of Nuts and Bolts

- Fundamental Role:

- Introduction to the idea that strength is not solely reliant on materials.

- Design considerations impact load-bearing capacity and durability.

- Load Distribution:

- Design’s role in evenly distributing loads across threads.

- Minimizing stress concentrations for enhanced strength.

- Thread Geometry:

- How the shape and form of threads contribute to strength.

- Design elements to prevent thread stripping and failure.

Calculations and Dimensions Involved in Designing High-Strength Nuts and Bolts

- Tensile Strength Calculations:

- Explanation of tensile strength as a critical factor.

- Calculations involving material properties and cross-sectional area.

- Yield Strength and Safety Factors:

- Incorporating yield strength for permanent deformation consideration.

- The role of safety factors in design to ensure reliability.

- Dimensions and Pitch:

- Importance of thread pitch in load distribution.

- Choosing appropriate dimensions for the application.

- Material Selection in Design:

- Integrating material properties into design calculations.

- Aligning material strengths with calculated requirements.

How Design Innovations Contribute to the Overall Strength and Durability

- Innovative Thread Designs:

- High-strength threads with optimized geometries.

- Improved load distribution and stress resistance.

- Advanced Material Combinations:

- Designing nuts and bolts with composite materials.

- Enhancing strength while reducing weight.

- Precision Machining Techniques:

- Incorporating precision machining for accurate thread profiles.

- Minimizing imperfections for increased strength.

- Coating Technologies:

- Introduction of coatings for corrosion resistance.

- Enhancing durability in challenging environments.

High-Strength Nuts and Bolts in Modern Construction

- Structural Integrity:

- Ensuring buildings and structures can withstand varying loads.

- The critical role of high-strength connections in preventing failures.

- Safety Considerations:

- Importance of robust nuts and bolts in ensuring safety.

- The impact of high-strength fasteners on overall structural safety.

- Durability and Longevity:

- High-strength nuts and bolts contribute to the long-term durability of structures.

- Reduced maintenance needs due to reliable connections.

- Advancements in Construction Technology:

- High-strength fasteners enabling the construction of taller and more complex structures.

- The role of these advancements in pushing the boundaries of modern architecture.

The Ubiquity of Nuts and Bolts in Daily Activities

- Invisible Essentials:

- Introduction to the often overlooked yet ubiquitous presence of nuts and bolts.

- Emphasizing their role as foundational components in our daily routines.

- Everyday Objects Connection:

- Noting how these fasteners seamlessly integrate into various aspects of life.

- Their presence in objects we interact with daily, from morning till night.

Applications in Households, Furniture, and Transportation

- In the Home:

- Nuts and bolts in furniture assembly.

- Applications in household appliances and fixtures.

- Furniture and Carpentry:

- Their essential role in constructing furniture pieces.

- Joinery in wooden items, showcasing versatility.

- Transportation:

- Securing components in bicycles, motorcycles, and cars.

- Their use in public transportation, contributing to safety.

The Role of Nuts and Bolts in Ensuring Safety and Reliability in Everyday Objects

- Safety in Everyday Objects:

- How nuts and bolts contribute to the stability of furniture.

- The role they play in securing crucial components in vehicles.

- Reliability in Appliances:

- Ensuring the reliability of household appliances.

- Their use in critical junctures to prevent accidents.

- Transportation Safety:

- Highlighting their contribution to vehicular safety.

- Securing parts that impact the functionality of automobiles.

As we’ve explored the intricacies of nuts and bolts, it becomes evident that their importance extends far beyond their size. These high-quality fasteners are the linchpin holding together structures in construction, ensuring the reliability of machinery in manufacturing, and contributing to the safety of everyday objects. The choice of materials, thread types, and design innovations collectively determines their strength, durability, and versatility across a spectrum of applications.

Nuts and bolts have stood the test of time, adapting to technological advancements and innovations. As we gaze into the future, these fasteners continue to evolve, embracing smart technologies, sustainability, and efficiency. Their enduring relevance in the ever-evolving landscape of construction and manufacturing reflects not only their simplicity and efficiency but also their adaptability to the changing needs of industries.

In a world where complexity often takes center stage, let us not forget to recognize and honor the humble nuts and bolts – the unsung heroes that bear the weight, connect the dots, and fortify the foundations of the structures that shape our lives.