Benefits of Small Scale Industries

Benefits of Small Scale Industries – Small-scale industries are the backbone of many economies, particularly in developing countries. They are defined as businesses that maintain revenues, assets,…

A Comprehensive Guide on When to Use Washers with Nuts and Bolts

When it comes to securing nuts and bolts, using washers might seem like a minor detail. However, these small metal discs play a crucial role in ensuring…

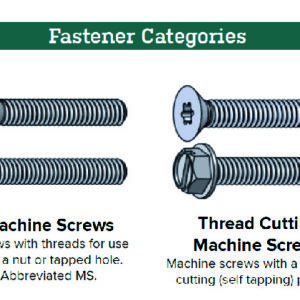

Fastener Information

Are you tired of struggling with fasteners and feeling overwhelmed by the various types and sizes available? Look no further! Our comprehensive Fastener Information PDF is here…

A Comprehensive Guide to Fasteners: Types of Bolts, Nuts, and Washers

Fasteners play a crucial role in mechanically joining and securing multiple parts together. However, their performance and service life are significantly influenced by factors such as type,…

Consider Using Through-Bolts for Stronger Woodworking Connections

When it comes to woodworking, many people instinctively reach for nails or wood screws to join their pieces together. However, there’s a better option in many cases:…

How to Fasten Pieces of Wood Using Nuts and Bolts

Fastening pieces of wood together using nuts and bolts is a common and reliable method in woodworking. This step-by-step guide will walk you through the process of…

How to Build a Wooden Nut and Bolt Bin: A Step-by-Step Guide

How to Build a Wooden Nut and Bolt Bin – Keeping nuts and bolts organized is crucial for any workshop or DIY enthusiast. Building a wooden nut…

How Do Nuts and Bolts Work with Wood – A Comprehensive Guide for Woodworkers

How Do Nuts and Bolts Work with Wood – Nuts and bolts play an integral role in woodworking projects, providing reliable and sturdy connections between wood pieces….